Northside Industries is a full-service provider of welding and fabrication solutions for a diverse range of industries. We maintain specialized systems and programs that allow us to manufacture a wide range of items under one roof.

Some of our systems and programs include MRP and ERP systems, EDI, Autodesk Inventor and AutoCAD Design Software. We are also able to provide a high caliber of service through our line sequencing, kanban pull system, and just-in-time delivery programs.

We strongly believe in reinvesting in our business and our staff, employing the latest technology and state of the art equipment to ensure a high-quality product, delivered in a timely manner for our clients.

Cutting

- Flow Waterjet

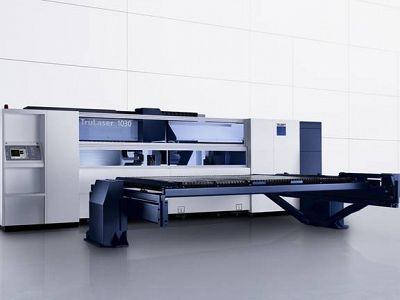

- Trumpf 1030 TruLaser

- Trumpf 3030 TruLaser

- Plasma

- Saws and Shearing

Our fiber laser delivers high-speed, high-precision cuts for large-format components with thickness capacities up to 1.5″, depending on the material type. The 80″ × 160″ bed allows us to take on complex projects with tighter tolerances and faster lead times.

Forming

- Accurpress Edge 250 Ton

- Accurpress Accell 235 Ton

- Trumpf 5170 TruBend

- Custom 100 Ton J-Bracket Forming Machine

- 8ft 4 roll system with CNC controls

This electric press brake features a 60″ bed and 55-ton capacity. It provides clean, repeatable forming for smaller parts with improved speed, consistency, and energy savings.

Welding

- Mig

- Tig

- Stick

- Gas

- Robotic

- Mobile

- Weld Passivation Machine

Coating

Northside Industries boasts a state of the art conveyorized powder coating machine with a multi stage pretreatment system that is the only one of its kind in Kelowna. We utilize our own paint line to ensure a higher quality, lower cost and faster turnaround for our clients.

Design

- Autodesk Inventor and AutoCAD design software